This digest was written by Atlas Policy Analyst Matthew Vining.

Earlier this month, Atlas published a case study on the Ultium Cells (Ultium) facility in Warren, Ohio, a $2.6 billion joint venture between General Motors (GM) and LG Energy Solution (LGES). Two of our very own, my colleagues Nicole Lepre and Tom Taylor, had the exciting opportunity to visit the battery cell manufacturing facility to speak with workers and management staff to better understand the facility’s role in the domestic EV manufacturing transition. In this exclusive opportunity with Ultium, we toured the facility itself, conducted original research, and interviewed 11 employees in various roles and levels of seniority at the facility. We also engaged with government officials, a chamber of commerce representative, an academic, and a local United Auto Workers (UAW) President to learn more about Ultium’s impact on the broader community.

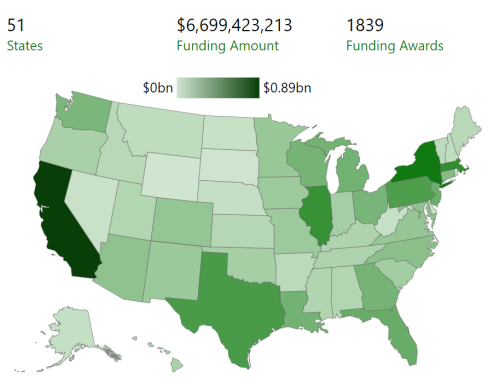

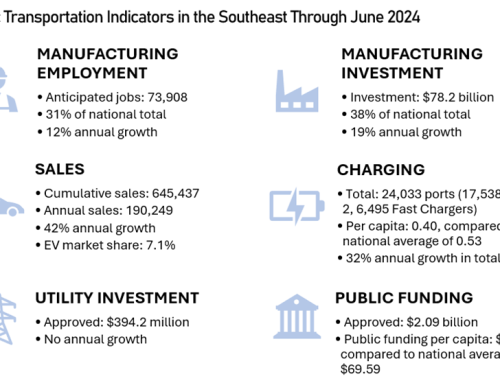

To date, companies have announced $205 billion in EV and EV supply chain manufacturing investments in the United States, three quarters of which have been announced since the passage of the Infrastructure Investment and Jobs Act (IIJA) in November 2021, per the EV Jobs Hub. All-time investments are expected to deliver 238,000 manufacturing jobs across more than 490 facilities. This case study focuses on one of these many facilities, Ultium Cells Warren, and its impacts on workers, the community, and the EV supply chain in the United States.

The case study touches on a number of key data points. Here are seven data points that are worth highlighting:

-

Americans want EV-based manufacturing jobs, and the process can be competitive. As of June 2024, there are nearly 2,200 hourly and salaried workers on site, surpassing Ultium’s employment expectations when they first announced the facility.

-

Inside the Ultium facility, it was clear that Ultium embodies modern manufacturing, marked by a clean and technologically advanced atmosphere. As a visitor, there was a feeling of witnessing a highly advanced operation.

-

The workers, most of whom were operating computers rather than physically handling tools or materials, came across as focused experts. Indeed, these workers spoke about how they had spent a considerable amount of time training, between seven and 19 weeks, to become experts in their roles.

-

Interviews with workers and the local UAW President provided insights into how the facility’s unionization and collective bargaining agreement were integral to creating good jobs at the facility. The UAW contract establishes a 63 percent increase in the starting wage, ensures a 30 percent raise over three years, and provides good benefits as well as other key provisions to enhance workplace safety and quality of life.

-

The value of good local jobs was particularly noteworthy in an area that has seen a sustained decline in manufacturing over the past few decades with limited other prospects for good jobs. Given the region’s struggle with the closure of GM’s Lordstown Assembly plant in 2019 and the decline of the steel industry, workers understood what it meant to have good-paying, local jobs with good benefits. Workers emphasized that without the Ultium facility, they would have had to move away from their homes for even the chance at a similarly fulfilling, well-paying job with good benefits. The average distance between home and work for hourly employees is 14.5 miles, which is significantly shorter than the 21-mile national average.

-

The Ultium facility is a key part of a broader supply chain ecosystem for the onshoring of EVs and EV infrastructure. Through their combined investment of $37 billion in the production of batteries and EVs, GM and LGES also support a network of suppliers, buyers, and materials recyclers across the country.

-

A key enabler of Ultium’s success in Ohio can be attributed to the support it has received from the federal government and state and local incentives. Most notably, the facility is the recipient of a portion of a $2.5 billion loan from the Department of Energy’s Loan Programs Office and tax credits (45X) from the IRA, as well as local and state subsidies.

Ultium has become part of a broader onshoring of the EV supply chain with support from the federal government. Read the full case study here.