Let’s talk EV supply chains and try to keep it a little breezy. As I only have so many words in this digest, consider this an appetizer with links to satiate your appetite.

The supply chain in EVs refers broadly to a version of the following components in the process:

-

Raw materials

-

Specialty chemicals

-

Battery components

-

Batteries

-

Technology components

-

Auto suppliers

-

Charging infrastructure

The further away from the consumer, the more “upstream” and the closer to the consumer the more “downstream.”

The supply chain is under some pretty serious stress. There is coverage of how the invasion of Ukraine is putting pressure on it, particularly for nickel. But the supply chain issues of course predated the invasion. These challenges in turn put cost pressures on electric vehicles. For instance, Tesla recently increased the price of its vehicles and Rivian tried to do likewise.

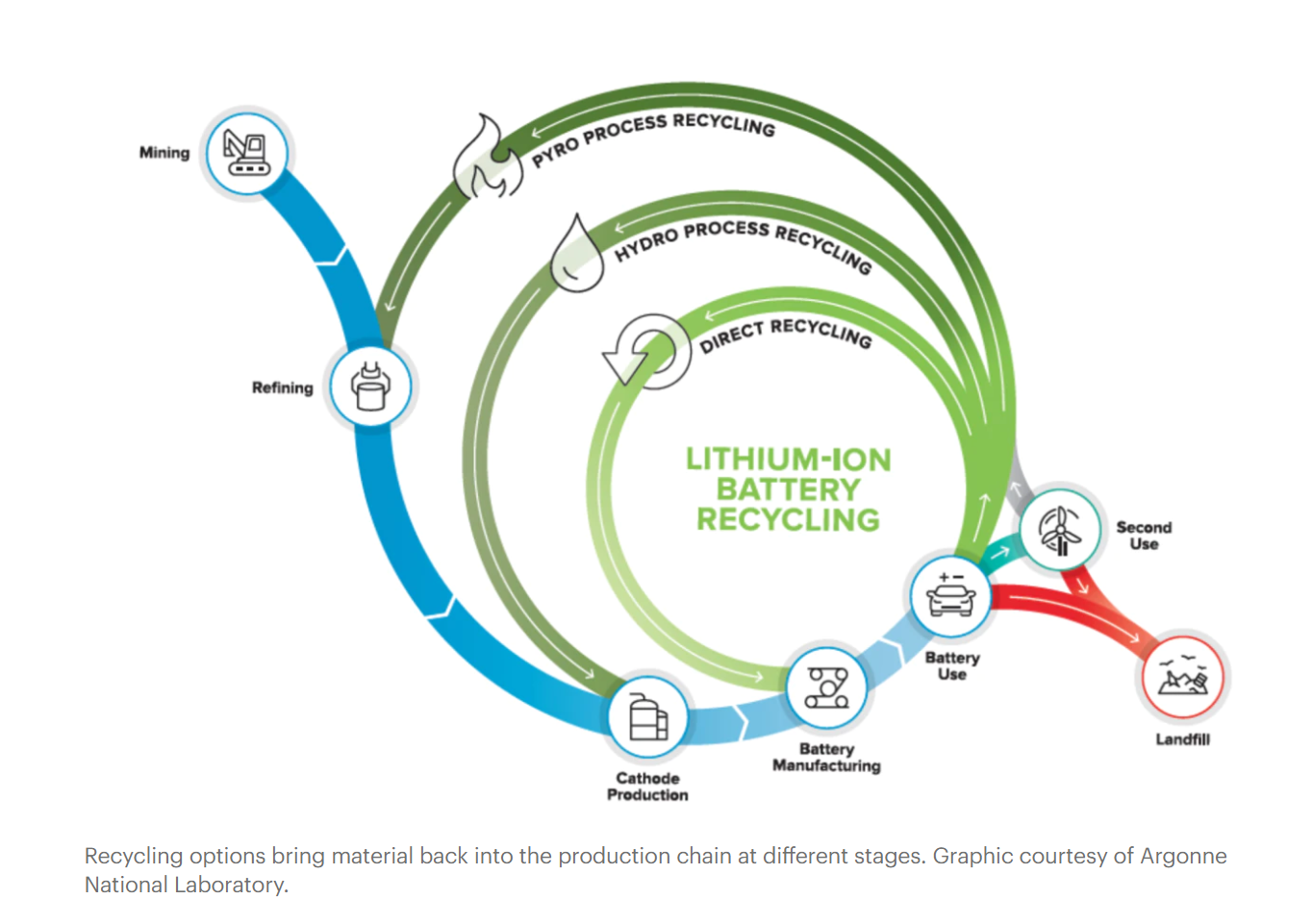

We are going to home in on the raw materials segment today – the furthest upstream. In particular, let’s look at three of the most talked about minerals critical for transport electrification: nickel, lithium and cobalt. All three are used in lithium-ion electric vehicle (EV) batteries.

There are projections about the materials needed moving forward. One projection summarized in the World Economic Forum found, “In the IEA’s 2021 sustainable development scenario of critical minerals, 80 percent of battery storage in 2040 would be used in light-duty electric vehicles, and this will require a 40-fold increase in the production of lithium and nickel and more than 20 times as much as copper, graphite, and cobalt compared with 2020 levels.”

We will need a lot more nickel, lithium, and cobalt. For each of these precious raw materials there are real concerns about the environmental and social impact of mining and ensuring that local communities benefit from extraction.

Let’s start with nickel. Nickel is important for battery range. The metal, however, is primarily used in stainless steel, and batteries are a very small part of global nickel demand (five percent). Supply shortages may come as soon as 2024, and so some automakers are attempting to design around this challenge. Russia is an important part of the supply chain for nickel – not in mining but in refining.

Next, lithium. The Alternative Fuels Data Center (AFDC) notes that “Most of today’s PHEVs and EVs use lithium-ion batteries, though the exact chemistry often varies from that of consumer electronics batteries.” Lithium batteries have high energy density. Here’s a podcast about the Salton Sea lithium production from geothermal brines in California and the enormous potential of that mine that could meet up to 40 percent of global demand. Resistance to lithium mining is significant and growing however, including opposition to a proposed mine in Nevada. It is important to note however that the California mine relies on a much less invasive approach than the open pit mine proposed in Nevada.

Finally, cobalt. There was a good New York Times Daily episode on cobalt, found here, and a powerful photo series here. Cobalt is key to supporting the cathode in lithium-ion EV batteries and cobalt is almost always a secondary extraction from larger nickel and copper ores, which means it is not independent in the process and requires significant processing to be battery-useful. Almost all of the processing takes place in China. Significant ethical and production concerns exist related to the mining of cobalt. In 2021, Congo supplied around 70 percent of the world’s cobalt, and batteries account for more than 50 percent of that cobalt. The mines and the miners often work in horrific conditions, with reports of child labor and poor safety standards. The Department of Energy also noted that cobalt poses the “highest material supply chain risk.”

While these three are the most common, there are also other raw materials important for the EV supply chain. This feature piece in Nature does a good job of breaking down the raw materials and the challenges in meeting the growing supply challenges. Copper and graphite will be in high demand as per projections and Elon Musk is talking up the potential of producing a manganese-based cathode. It is time, it seems, to get out the periodic table again.